June 20, 2025, 3:20 am | Read time: 4 minutes

Angle grinders are used both on construction sites and for some DIY projects. The DIY twins, Julian and Marian, explain how to properly use the tool for various applications and what to watch out for during operation on “Easy Tools”!

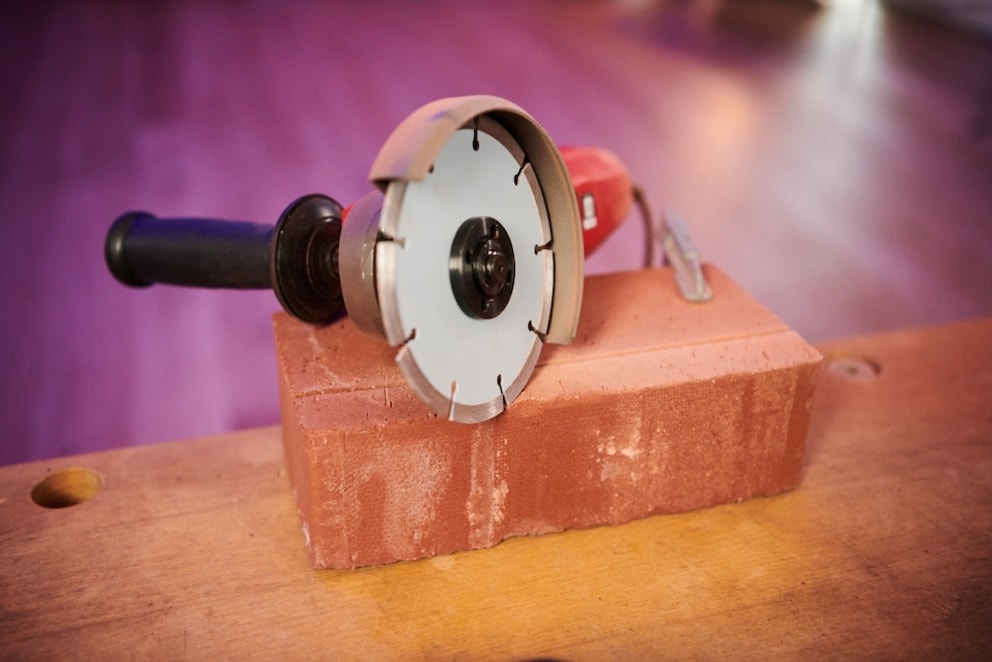

The angle grinder, commonly known as a “Flex,” is a classic tool found on almost every construction site–and in many home workshops. To get the most out of the device, there are several things to consider, especially when choosing the right disc. At “Easy Tools,” you can learn what an angle grinder is suitable for and what to watch out for when working with this powerful tool.

What an Angle Grinder Is Suitable For

The angle grinder is one of the most frequently used hand tools for cutting and grinding tasks. Equipped with various discs, it is suitable for numerous applications and materials. With its rotating disc, it enables cutting tasks as well as effective material removal on various surfaces.

The wide range of applications includes working with metal, plastic, and wood. With the right disc, you can rework weld seams, remove rust, or sand off paint residues.

By the way: The angle grinder owes its name to the 90-degree angle gear that redirects the drive power to the grinding spindle. This design clearly distinguishes it from other grinding machines.

Related: The 5 Best Cordless and Corded Angle Grinders Reviewed

The Right Disc for the Angle Grinder

For rough material removal on metal, grinding discs are the first choice. They are used for tasks such as deburring or removing protruding weld seams.

Flap discs, on the other hand, consist of overlapping flaps with abrasive grains and provide a particularly uniform and low-vibration grinding result. They are suitable for:

- Surface grinding

- Weld seam processing

- Edge grinding

- Removing rust or paint residues

- Smoothing wood or cast iron

How to Change the Abrasive

Changing the disc is similar for many devices. Usually, a suitable wrench is included. Additionally, you should consult the user manual of the specific angle grinder. Generally, proceed as follows:

- Fix the lock

- Loosen the nut

- Replace the disc

- Secure the nut correctly again

Overview of Different Power Classes

Depending on the area of use, there are three main classes:

- Compact devices with a disc diameter of 115 to 125 millimeters are suitable for lighter grinding tasks with a power of about 750 watts.

- All-round models with a diameter of 150 to 180 millimeters offer around 1,000 to 1,700 watts and are universally applicable, especially for grinding.

- Powerful professional machines with a disc diameter of 230 millimeters and about 2,000 watts are designed for more intensive cutting and removal tasks and are primarily used on construction sites.

Pay Attention to Speed Limitation

“The idle speed of angle grinders ranges between 11,000 and 13,000 revolutions per minute. This means more power, but also more vibration. Speed-regulated devices with medium power are often the better choice for home use.”

Tips for Clean Results

Some simple rules ensure clean and safe work:

- Do not start the device on the workpiece; instead, place it after reaching the speed.

- When grinding, ideally work at an angle of 30 to 35 degrees with light pressure.

- Slow, steady movements achieve a better result.

- Regularly remove grinding dust with a damp cloth–this prevents clogging of the abrasive.

- Clean dull abrasive before use.

- Always work paint and wood surfaces completely and evenly to avoid staining.

- When sanding wood, first remove material across the grain, but finish along the grain.

- Remove only as much material as necessary–and choose the appropriate abrasive for this.

Important Safety Aspects

With up to 13,000 revolutions per minute, the angle grinder is not a toy–and is more suitable for experienced DIY enthusiasts. To avoid injuries, follow these rules.

- Before first use, thoroughly read the user manual and safety instructions.

- Also, conduct a test run without load before each use.

- Only use suitable discs–never use cutting discs for grinding.

- Observe the maximum speed. This is indicated on each disc.

- Abrasives have an expiration date, usually three years. Do not use expired discs.

- Only use appropriate accessories approved for high speeds–no drill attachments!

- If there is imbalance or vibration, do not continue using the device and abrasive.

- Only change discs after disconnecting the device from the power supply.

Note: Even single-handed devices should always be operated with both hands. A secure stance is mandatory! The workpiece must be firmly clamped, but never the tool itself.

Tips for Finding the Ideal Juicer

Combination wrench: What to consider when purchasing

Should you scarify lawn in the fall? A professional explains

Protective Equipment and Work Environment

Personal protective equipment is essential–safety glasses, dust mask, and hearing protection are part of the basic equipment. Clothing must also be appropriate: It should be tight-fitting and not easily flammable. Loose clothing and long hair are dangerous as they can get caught in the device.

Finally, the work area is crucial, as sparks can fly depending on the material. Therefore, remove flammable materials beforehand! This makes working with the angle grinder not only effective but also safe.